Inventor of AI Intelligent PVC Dispensing Machine | 18 Years of Industry Leadership

Hot Products

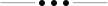

Intelligent High Speed 4 colors soft rubber PVC/silicon Patch filling machine

Intelligent High Speed 8 colors soft rubber PVC/silicon Patch filling machine

Intelligent High Speed 4 colors soft rubber PVC/silicon Patch filling machine

Teach-box & computer doubel programs 24 colors soft rubber PVC patch filling machine with UV lamp (DSP system)

Why Choose Us

Weldo implants brains and eyes into machines

Increase productivity

High-speed and stable operation: The automation equipment can continue to operate stably at a speed far exceeding that of manual labor, greatly shortening the production cycle.24-hour uninterrupted work: It can work continuously for a long timewithout manual intervention, except for the necessary maintenance time, there will be basically no downtime, and the equipment utilization rate can be effectively improved.

Weldo implants brains and eyes into machines

Improve product quality

High-precision production: With advanced sensors and precise mechanical structure, the automation equipment can accurately control various parameters in the production process to ensure that the dimensional accuracy and appearance quality of the product are highly consistent.

Enhance production safety

Weldo implants brains and eyes into machines

Replace dangerous operations: In some hazardous environments or dangerous processes, such as high temperature, high pressure, toxic and harmful places, automation equipment can replace manual operation to avoid personnel injury.Reduce the risk of safety accidents: The operation process of automation equipment is relatively stable.

Reduce production costs

Weldo implants brains and eyes into machines

Reduce manpower investment: The application of automation equipment can greatly reducemanual operation positions, and reduce the cost of manpower recruitment, training, salary and benefits. Reduced raw material waste: Through precise control and optimized production processes, automated equipment can use raw materials more accurately, reduce raw material waste caused by improper human operation, and reduce raw material costs.

Popular Production Mode

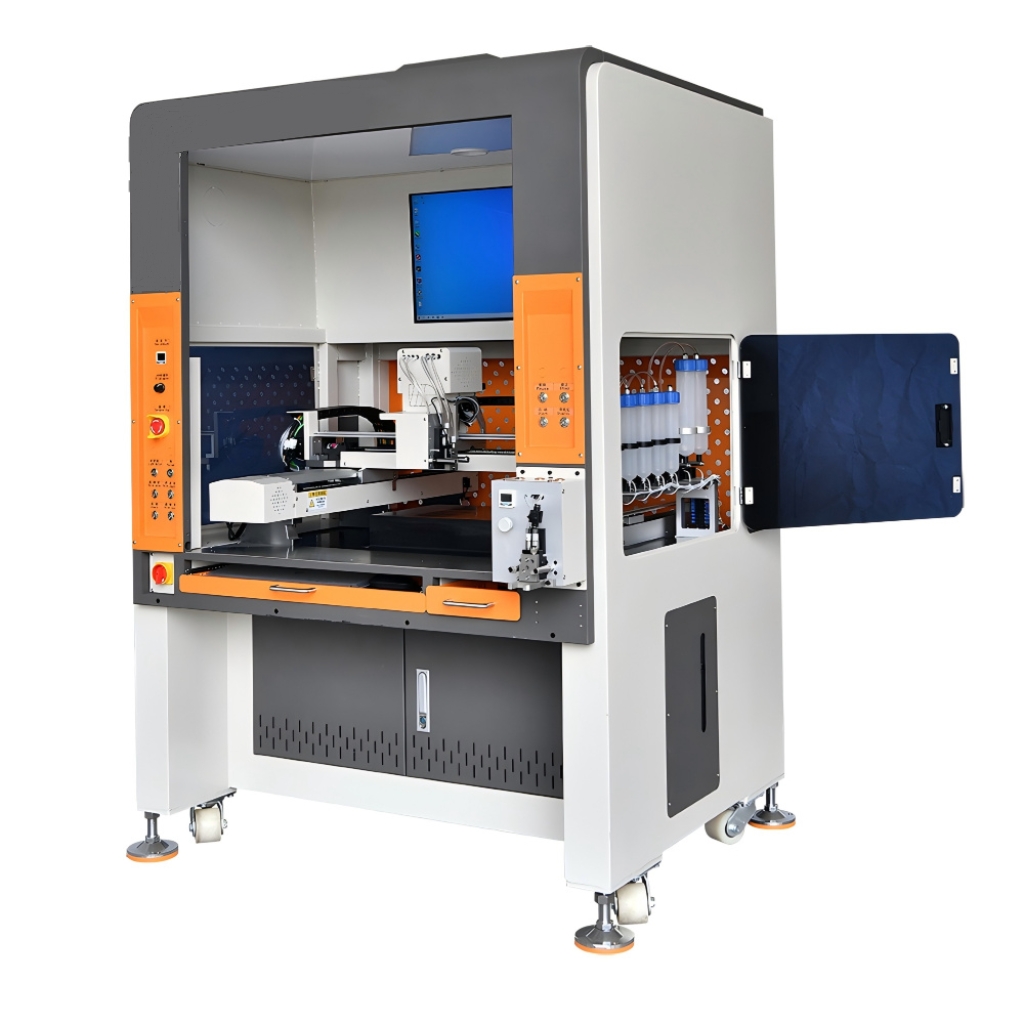

Rubber PVC patch L model production line ( 2 sets of rubber patch filling machine + 1 set of digital oven)

Rubber PVC Patch Circle model production line ( 1 full automatic heating, cooling and mold pushing production line + 2 sets of face color filling machine + 1 set of base color filling machine

Rubber PVC patch U model production line ( 2 sets of rubber patch filling machine + 1 set of digital oven)

small automatic rubber PVC patch production line with robot

Company Profile

Wisedo is a national high-tech enterprises that located in DongGuan, integrates R&D, producing ,marketing and service.With more than a decade years self-cultivation, Weldo developed software,hardware designing and technical application system based on machine visual,motion control,liquid control and AI technologies.

Wisedo has a professional team including 2 doctoral,6 experienced engineers,16 service engineers.Maintain long-term technical R&D cooperation with universities and institutions such as SCUT.Weldo owned lots of patents and software copyrights, invited kinds of high-tech products,and achieved software certification.

17 year of R&D

Experience

$30,000,000

Annual Output Value

3000m

Factory Area

2

Wisedo focus on vision,control and AI technology, innovates continuously,provides global customers with automated, intelligent solutions for traditional industries. Create value for customers and become a leading brand in the target market.

Technical strength in product development

and innovation

We can provide reliable technical support and after-sales service.

Our machines are easy to operate and stable in production.

Our equipment is able to improve production efficiency, reduce labor and improve product quality.

Application

News

Eight Advantages

Support 2-24 color dispensing to

meet complex process needs.

Provide computer and handle programming, flexible and efficient

Automatic needle alignment system, ensures precise positioning and consistent results

Support PVC, silicone and other materials dispensing.

Intelligent dispensing for improved efficiency and product quality.

Flexible configuration to adapt to different production capacity needs.

Provide non-standard customization to meet individual needs

Equipped with UV lamp, dispensing and curing are completed simultaneously.

Frequently Asked Questions and Answers

Fully automatic PVC liquid silicone dispensing machine

Create a different model

.png)

.jpg)

.png)

.jpg)

.jpg)

.jpg)